• Dronten (NL) • Sliedrecht (NL) • Hohenwart (DE) • Hamburg (DE) • Großwallstadt (DE) • Boekarest (RO)

Vibratory hammers and Power packs

Vibratory hammers and Power packs

• Individual advice

• Suitable equipment

• Normal-frequency

• High-frequency

Ambient factors, support when selecting equipment, working principle. Capacity that can be calculated.

Choosing the right machine is crucial for the economic and technical success of vibration work. We offer our customers individual advice to enable them to select suitable equipment, taking into account all the relevant factors – such as the building site and the geological and technical requirements.

Ambient factors

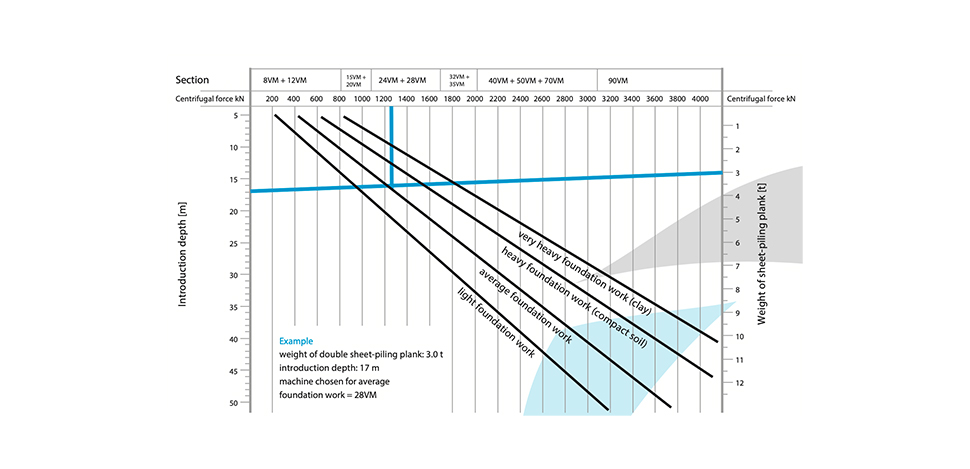

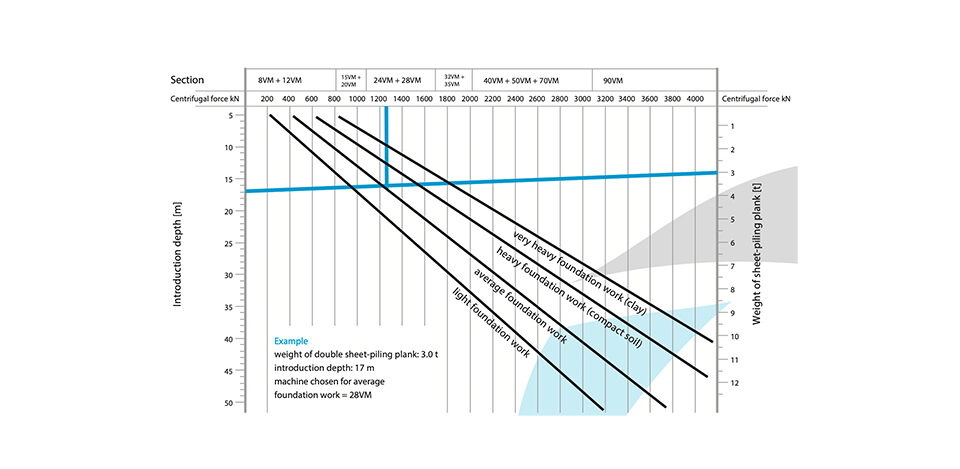

The type of vibrator that will be suitable specifically depends on the size and the weight of the foundation elements to be introduced, the introduction depth and the soil condition. In principle, the centrifugal force and the amplitude must be chosen such that the shaft friction and the toe resistance between the foundation element and the surrounding soil can be overcome.

Support when selecting equipment

The nomogram below will help you select the right equipment or the required centrifugal force – depending on the soil properties and the weight and introduction depth of the foundation elements.

Additional equipment such as rinsing lances or pre-boring rigs can be used in order to achieve considerably better results with the same dimensions or centrifugal force. The power delivered by the power pack must be sufficient to achieve the required momentum and, as a result, the required centrifugal force in difficult soil. The drive power must be 2-3 kW per 10 kN of centrifugal force.

Please feel free to contact one of our expert advisers for personal advice when selecting the equipment, based on soil conditions and foundation elements. They will use simulation software to determine the optimum machine for your project.

Support when selecting equipment

Support when selecting equipment

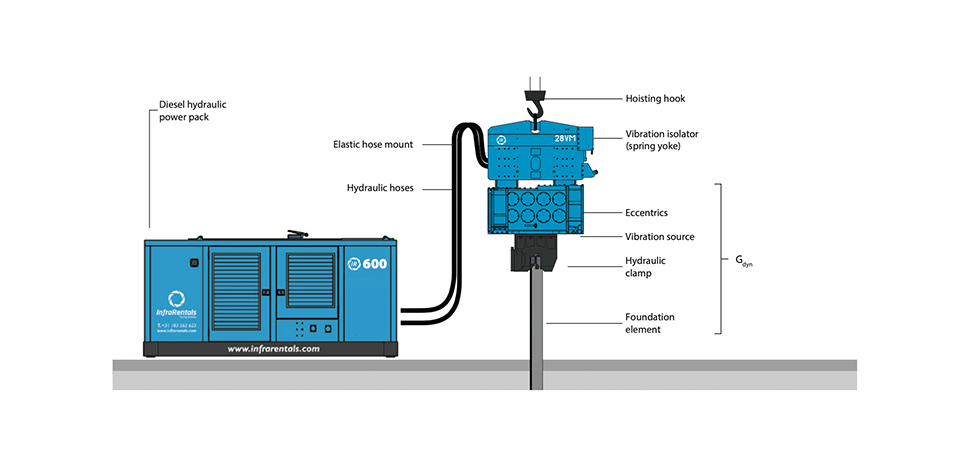

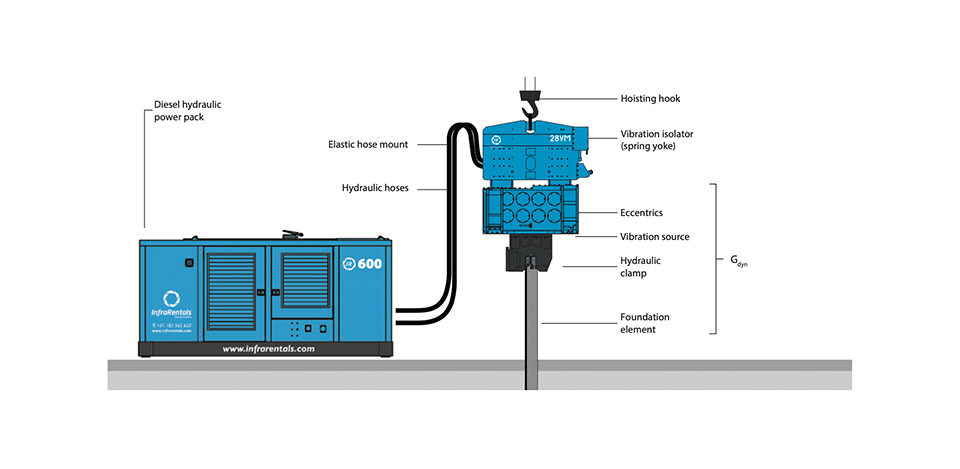

Operating principle of InfraRentals

Operating principle of InfraRentals

Important formulas in vibration technology

Static moment M [kgm]

The static moment (eccentric moment) determines the extent of the imbalance. As the determining factor for the amplitude, this is a crucial value in foundation work.

Speed (vibration frequency) n [min –1]

Number of revolutions (vibrations) per minute. The speed determines the vibration frequency at which the system is moved to and fro. The foundation element transfers the vibrations to the surrounding soil. This significantly decreases the shaft friction between the foundation element and the soil. High frequencies prevent unintentional propagation of vibrations through the soil.

Centrifugal force

The centrifugal force must be sufficient to overcome the static friction between the foundation element and the soil (separation effect). The centrifugal force greatly influences the decrease in shaft friction and is also important as an impact force in order to overcome the toe resistance.

Amplitude S [m]

Together with the centrifugal force, the amplitude is a measure for the introduction power. A high gear ratio and high impact force provide the proper vibration drive. Carrying out vibration and pulling activities in compact soil requires a strong amplitude in order to overcome the friction between the foundation element and the soil.

Acceleration a [m/sec 2]

The acceleration of the foundation element being transmitted to the surrounding soil causes the soil particles to be displaced; the friction between soil particles is reduced as is the soil resistance.

Normal-frequency or high-frequency (HFV) InfraRentals vibrators. The right choice for every application.

The eccentrics of the high-frequency series can be adjusted while working. This series is used wherever there are major restrictions

as regards the propagation of vibrations in the soil, such as when working near existing buildings or in town centres. This equipment avoids resonances when starting and stopping and it enables an optimum amplitude, matching the soil characteristics, to be set.

Check out our vibratory hammers

Normal frequency vibratory hammers

High frequency vibratory hammers

High frequency vibratory hammers with swivel head

Resonance free high frequency vibratory hammers

Resonance free high frequency vibratory hammers with swivel head

Side gripper excavator mounted vibratory hammers

Ring vibratory hammers with variable moment

Leader guided vibratory hammers with variable moment

Add-on Vibrators HVR

+31 (0)183 562 623

+31 (0)183 562 623